Rotating Roller Brushes (Made to your

Specifications)

Rotating Roller Brushes (Made to your

Specifications)

Fill: Poly, Genuine Nylon, Pure Horse Hair, Union Fibre, Tampico Fibre, Brass Wire, Steel Wire or Polyester.

Punched Roller Brushes

Punched Roller Brushes

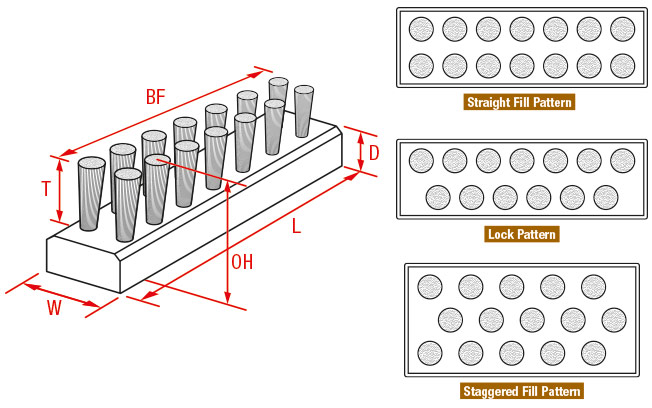

Punched Roller Brushes are made by stapling knots of fill material into nylon or polyethylene core, which has been pre-drilled. With either core they can be refilled once the brush bristle have worn. A variety of fill patterns and density can be obtained.

Purpose: These brushes are preferred in many applications where steel or aluminium core are prone to corrosion or acid attack.

- Tomato Cleaning

- Fruit Cleaning or Polishing

- Glass Washing Manufacturers

- Printing Industry

- Food Processing Industry

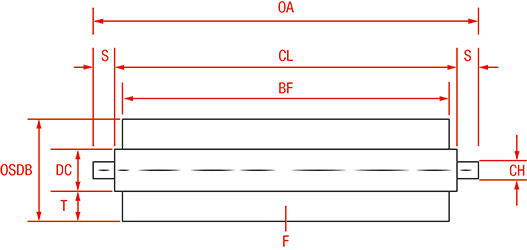

The Measurements

required when ordering Roller Brushes are as follows.

The Measurements

required when ordering Roller Brushes are as follows.

- Overall Length including Shaft (if applicable) = OA

- Core Length = CL

- Brush Face Length = BF

- Shaft if required = S

- Outside Diameter = OSDB

- Centre Hole (Bore) = CH

- Diameter of Core = DC

- Trim (Length of Bristle) = T

- Fill Material = F

- Density

- Application

- Pattern Fill (eg. Staggered, Spiral, Parallel or Herringbone)

Rotating Roller Brushes

(Made to your Specifications)

Rotating Roller Brushes

(Made to your Specifications)

Fill: Poly, Genuine Nylon, Pure Horse Hair, Union Fibre, Tampico Fibre, Brass Wire, Steel Wire or Polyester.

Purpose: Spiral or Industrial Roller Brushes, Cleaning and Polishing Fruit, Conveyor Belt, Cleaning Brushes, Road Sweepers, Factory Sweeper, Coal Mines, Salt Fields, Sugar Mills, Metal Mines, Cotton Gin Fields, Glass Washing Manufacturers

Spiral Wound Strip Brush

Rollers:

Spiral Wound Strip Brush

Rollers:

Spiral Strip Brush Rollers are made by winding strip brush onto a shaft or core. For light work it may be more suitable to open up the strip to achieve a less dense fill and hence more flexible brush. For heavy work or where greater pressure will be required it is more of an advantage to closely wind the strip brush. Spiral Wound Strip Brushes can be supplied on refillable core, onto a shaft or can be supplied as a loose coil.

The

Measurements required when ordering Roller Brushes are as follows.

The

Measurements required when ordering Roller Brushes are as follows.

- Overall Length including Shaft (if applicable) = OA

- Core Length = CL

- Brush Face Length = BF

- Shaft if required = S

- Outside Diameter = OSDB

- Centre Hole (Bore) = CH

- Diameter of Core = DC

- Trim (Length of Bristle) = T

- Fill Material = F

- Density

- Application

- Pattern Fill (eg. Spiral, Parallel)

- Pitch = P

Strip Brushes

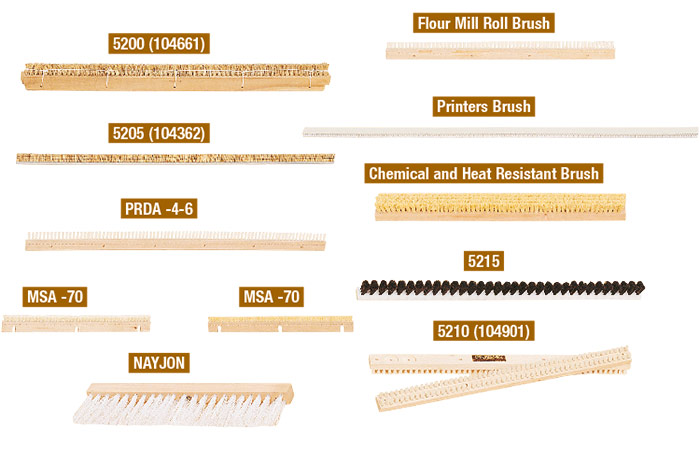

Punched Strip Brushes:

Punch Brushes are made by stapling knots of fill material into either timber, nylon or polyethylene bases, which has been pre-drilled. With the polyethylene bases they can be refilled once the brush bristles have worn. A variety of fill patterns and density can be obtained.

Purpose: Brushes used in the Food Industry, Cleaning, Industrial Process, Machinery, Conveyor Belt Cleaning, Flour Mill Industry, Printing Industry,

Wood/Polyethylene Strip Brushes:

Fill: Poly, Nylon, Pure Horse Hair, Union Fibre, Tampico Fibre, Brass Wire, Polyester and Bassine.

Flour Mill Brushes (Made to your Specifications)

- 5200 1 metre (40”) long - Wooden Base

- 5205 1 metre (40”) long - Channel Strip Brush

- 5210 Le Coq Brushes - Nylon Fill - Wooden Base

Printing Brushes (Made to your Specifications)

5215

The Measurements required when

ordering strip brushes are as follows:

The Measurements required when

ordering strip brushes are as follows:

- Overall height = O.H.

- Trim = T

- Length = L

- Width = W

- Depth/Thickess = D

- Brush Face = B.F.

- Number of Rows = R

- Nature and diameter of filament

- Use of which brush is intended

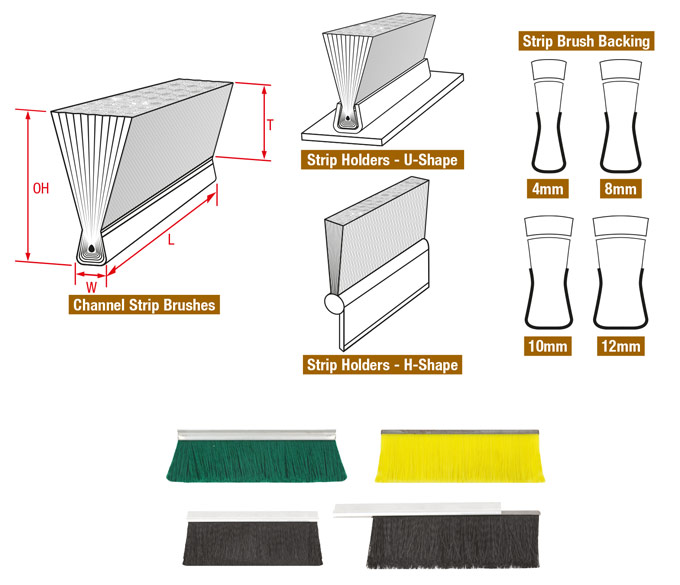

Channel Strip Brushes

Channel Strip Brushes

Channel Strip Brushes (Strip Brushes are made to order)

They are made by filling Brush Fibres into a continuous metal channel. The Fibres are held into the channel by a central rod which is then held in place by closing the sides of the channel. Strip Brushes may be cut to straight lengths or manipulated in the factory to form a multitude of brushes.

Purpose: Machine Guards, Doors and Dust Seals, Printing, Industrial Process Machinery, Truck and Coach Wheel, Arch Brushes, Securing, Cleaning, Vacuum, Industrial Machine, Food Processing Industry

Strip Brushes - Channel Strip Brushes (Made to your Specifications) - Any length & stiffness

Fill: Poly, Nylon, Pure Horse Hair, Union Fibre, Tampico Fibre, Brass Wire & Polyester.

Width Profile

Code No:

- 5300 4mm

- 5310 6mm

- 5320 8mm

- 5330 12mm

Aluminium Holder

- 5340 h = 8mm Holder

- 5350 h = 4mm Holder

- 5360 U = 8mm Holder

Aluminium Holder

- 5380 Extra Large

- 5385 Large

The Measurements

required when

ordering strip brushes are as follows:

The Measurements

required when

ordering strip brushes are as follows:

- Overall height = O.H.

- Trim = T

- Length = L

- Width = W

- Nature and diameter of filament

- Use for which the brush is intended